Mobile Industrial vacuum cleaner for collecting chemical aggressive liquids

Vacuum Cleaner for collecting chemical aggressive liquids designed for safe and effective cleaning of liquids, acids and alkalis. This is the preferred choice in various industries, in particular, associated with an aggressive environment in which the same vacuum cleaners quickly expire their resources.

Designed to work in a wet environment, as example, in places where store acids and alkalis and other kind of chemicals, or for liquidation chemicals spilling. And also, during cleaning of industrial equipment where using a liquid detergent. All parts of vacuum cleaner, which can be wetted, made of thermoplastics, depending on the chemical resistance of the materials relative to the collected media:

- PP-С (polypropylene block-copolymer) – T of exploitation -40 – +80 0C;

- PЕ – polyethylene low pressure, T of exploitation -50 – +80 0C;

- PVC – polyvynilchloride, T of exploitation 0 - +60 0C;

- PP-S –fire retardant polypropylene, T of exploitation 0 - +100 0C;

- PVDF – polyvinylidene fluoride (high chemical resistant), T of exploitation -30 – +140 0C;

- К – chemical resistant fiberglass, T of exploitation -40 – +105 0C.

The environment for which the acid vacuum cleaner is designed is dangerous for health. Therefore, the device is equipped with an adsorption filter for adsorption of gas, vapors and smoke.

Features and advantages which has been designed in the vacuum cleaner for collecting acids and alkalis:

- Using for cleaning chemical aggressive liquids

- Maximal safety

- Roller trolley made of stainless steel

- Chemical resistance wheels

- Ball valve for safe draining of fluid

- Filter changes quickly and without tools

- Level filling Indicator

- Easy in operation and maintenance.

Technical characteristics

Both quantity of fans | 2 pcs. |

One fan power | 1,4 KW |

Voltage (V / ~ / HZ / A) | 230 V/АС/50-60 Hz /16А |

Maximum underpressure | 200/20 mbar / kPa |

Nominal air flow | 280 m3/h |

Collector type | container |

Both capacity of container | 40 L |

Type of filter | replaceable cartridge |

Filter area | ~5.000 sm3 |

Filter cleansing | cartridge replacement |

Inner diameter of collecting hose | 38 mm |

Working noise level, dB | 65 dB |

Overall proportions, L * W * H mm | 900*500*1200 |

Weight | 73 кг |

Mean time to failure (replacement of electro brushes), h | No less than 1000 h. |

Operation mode of device | continuous, non-stop |

Temperature of exploitation area | -20 до +40 °С |

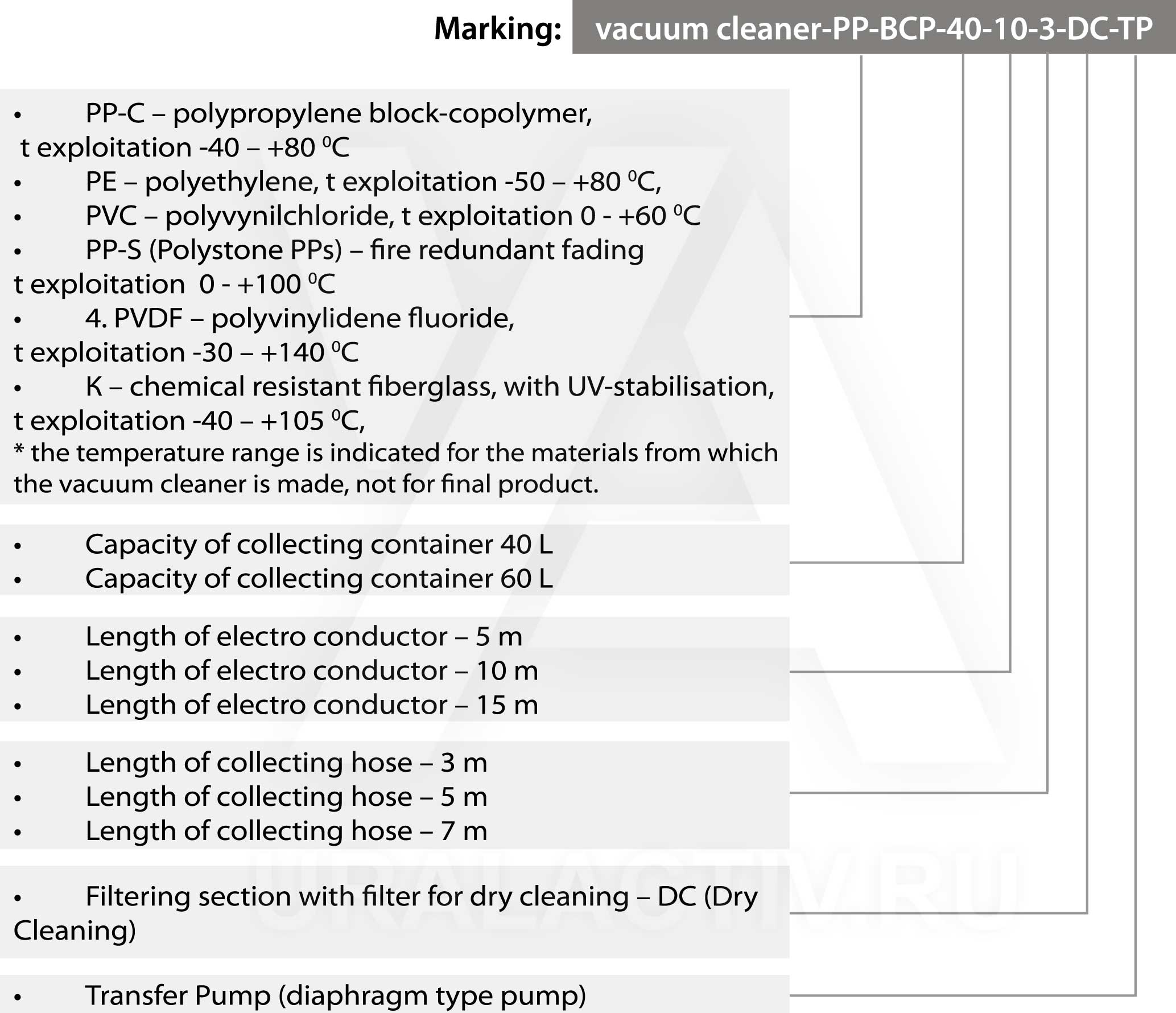

Vacuum cleaner options

- Capacity of container for liquids collection: 40L, 60L.

- Length of electro cable: 5m, 10m, 15m.

- Length of collecting hose: 3m, 5m, 7m.

- The kit of vacuum cleaner included: vacuum cleaner handle for attachment nozzle, brush, crevice tool. Also possible to make specialized nozzles for collecting media in difficult places.

- The vacuum cleaner is designed for collection liquids and mixes of dry chemicals with liquids – collecting only dry chemical / dry garbage is not possible, because the filter will be quickly clogged. For collecting dry garbage a vacuum cleaner kit can be ordered with replacement filter section, which will contribute to correct operation of the vacuum cleaner in process of collecting and cleaning a dry garbage.

- The vacuum cleaner can be equipped with a transfer pump for safe pumping of liquids. Therefore, liquids can be pumped in a "closed loop" system without interrupting the cleaning process.

- As option is possible to manufacture explosion-proof vacuum cleaner.