Carbone Ventilation Filter HIMVENT-U

The adsorption filters manufactured by UralActiv Ltd. are special equipment for protection of environment.

Basically, for the effective removal of organic pollutants, aggressive gases and harmful odors from industrial gas waste must be performed adsorption of the gas mixture by a porous solid adsorbent - activated carbon is used.

Activated carbon is selected as the main sorbent in ventilation carbon filters HIMVENT-U.

Carbon has the advantages of high adsorption efficiency, wide application range, convenient maintenance, and the ability to handle various mixed exhaust gases at the same time.

Carbon ventilation filters HIMVENT-U are specially designed to solve the problems of ventilation and air purification:

- in industrial laboratories, research laboratories, various institutions as absorbers of harmful gases in the overflow and mixing various chemicals, including acids.

- at the manufacture of industrial enterprises:

- during separation and purification of gases ;

- during cleansing of the air;

- in process of cleaning petrochemical waste gases;

- in process of cleaning natural gas and associated petroleum gas;

- in capturing solvent vapors;

- fume gases cleansing;

Technical parameters ventilation filtering units ChimVent

Ventilation filtering unit HIMVENT | Unit Design | ||

H– horizontal | V– vertical | ||

Equipment items | Laboratory Fan HIMVENT-Н-L 164 | ||

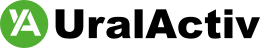

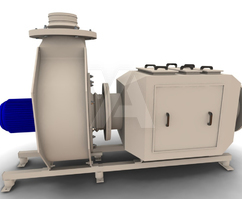

Ventilation Carbon Filter HIMVENT-U-H horizontal type | Ventilation Carbon Filter HIMVENT-U-V vertical type | ||

The knot parts | mechanical preliminary purification stage filter * | ||

intermediate stage cleaning filter | |||

Final purification stage filter. Adsorption filter. | |||

Dimension sizes | Length,m. | 1500 | 1300 |

Height,m. | 800 | 1200 | |

Width,m. | 730 | 730 | |

| |||

Diapason of efficiency in operating mode m3/h | Voltage supply, 380 V, 50 Hz | Working power kW | Additional spare discharge at the input, Pa (under the duct network). |

560 ÷ 1500 | 380 | 0,55 | 700 ÷ 160 |

*- Not included in the basic unit, ordered by customer.

For optimal selection of ventilation carbon filters HIMVENT the customer should answer to number of basic questions about the expected conditions of the equipment operation, including the characteristics of the air-gas mixture:

- required volume of air-gas mixture, m3/h.;

- design values of temperatures of the air-gas mixture at the inlet and outlet of the air duct system, оС;

- cyclical temperature changes of the air-gas mixture;

- chemical composition of air-gas mixture;

- short description of the formation of an air-gas mixture;

- room dimensions for equipment placement;

- grade of material provided by the project;

- shift work of technological equipment, etc.