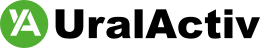

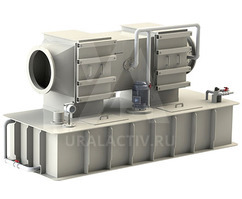

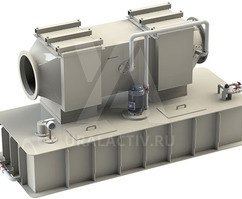

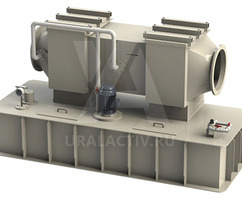

Gas washer HIMVENT, type «GM-4»

Double-stage wet horizontal gas washer «GМ-4» has packed packed chamber and multi-stage polymeric demister system. It is intended for many acids, alkalis and their mixtures.

Principle of operation

Scrubber «GМ-4» works on binding principle of airborne, vapours and dust particles with scrubbing liquid. The airflow gets through the packed chamber that is irrigated continuously with water (solution) by sprayers. They spray the liquid in two directions: against airflow and along airflow. Due to the nozzle in the packed chamber the contact area of liquid with gas-air mixture increases and it improves the efficiency of cleaning. The process of catching is available in wet scrubbers due to condensing effect – enlargement of vapours and particles due to the condensation of water vapours on them.

After the air flow with contaminants combined by scrubbing liquid transfers in demisters where the scrubbing liquid is segregated from gas-air mixture. Due to bends of demister’s profile the drops are settled on the surface and after they flow down in drain chamber from which the scrubbing liquids goes to the buffer vessel through the hydraulic seal. The hydraulic seal enables the discharged operation of scrubber. After that the liquid is transferred by means of pump for cleaning. The gas washer can be equipped with coagulator optional. The coagulator is integrated between demister’s elements accordingly that the smallest particles can enlarge and segregate on demisters.

Attention! On customer’s request we can complete this type of gas washer with fibrous filter cassette. It provides more quality cleaning from the most hard-separable small aerosol particles.

TYPES OF CASING

- Left with side load

- Right with side load

- Left with topload

- Right with topload

Additional configuration of gas washer HIMVENT GM-4

Described in this catalogue gas washer GM-4 can be equipped optional with the fibrous filter cassette FVG-PP-UA.