Wet vertical gas scrubbers

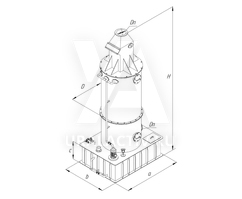

The wet vertical gas washer, type HIMVENT is intended for air cleaning from many acids, alkalis and their mixtures including impurity gases.

Principle of operation

Gas washer HIMVENT has big nozzle layer that enables to use this gas washer as an absorber. The airflow gets from the bottom upwards through the nozzle layer that is irrigated continuously with water (solution) by sprayers. Due to the big size of nozzle the contact area of liquid with gas-air mixture increases and it improves the efficiency of cleaning.

After the air flow transfers in demisters where the scrubbing liquid is segregated from gas-air mixture. Due to bends of demister’s profile the drops are settled on the surface and after they flow down in drain layer. The scrubbing liquid goes through the nozzle layer and then it transfers to the buffer vessel through the hydraulic seal. The hydraulic seal enables the discharged operation of scrubber. After that the liquid is transferred by means of pump for cleaning.

The gas washer can be equipped with coagulator optional. The coagulator is integrated between demister’s elements accordingly that the smallest particles can enlarge and segregate on demisters.

Vertical scrubbers are divided into three types according to the flow rate

- HIMVENT-05 – scrubber with flow rate 0.5 m/s, resistance until 550 Pa

- HIMVENT-1 – scrubber with flow rate 1.0 m/s, resistance until 600 Pa

- HIMVENT-2 – scrubber with flow rate 2.0 m/s, resistance until 650 Pa.