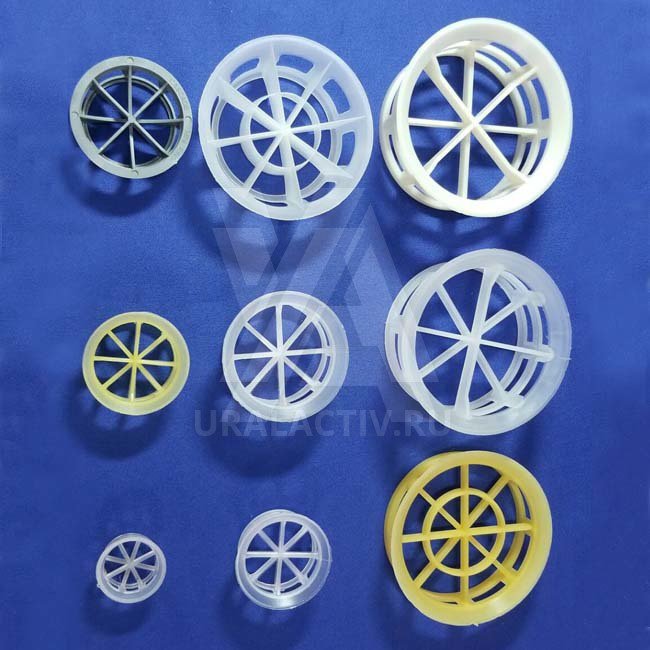

Plastic cascade mini ring (CMR)

Plastic Cascade Mini Ring (CMR) is a modern chemical top cap made of heat-resistant and chemically resistant plastics such as:

- polyethylene (PE)

- polypropylene (PP)

- reinforced polypropylene (RPP)

- polyvinyl chloride (PVC)

- chlorinated polyvinyl chloride (CPVC)

- polyvinylidene fluoride (PVDF)

Plastic cascade mini ring is applied in absorption and cleansing.

The main advantages of plastic cascade mini rings (CMR):

- Economic feasibility

- High productivity

- The variety of sizes

- Open structure and preferred vertical axis orientation preventing contamination by allowing solid parts to be more easily flushed through the liquid layers.

- The design of the ring and spokes and the preferred vertical orientation provides a high mechanical strength. That allows the use of these top caps in deep packed columns.

Dimensions Ø × height × thickness, mm | Specific surface, m2/m3 | FreeVolume | Количество шт./м³ | Quantity, pcs/m3 | Dry packing factor | |

|---|---|---|---|---|---|---|

16*8.9*1.0 мм | 5/8" | 370 | 0.85 | 299136 | 135.6 | 602.6 |

25*17.5*1.0 мм | 1" | 228 | 0.90 | 81500 | 65.2 | 312.8 |

38*19*1.2 мм | 1.5" | 132.5 | 0.91 | 27200 | 54.5 | 175.8 |

50*25*1.5 мм | 2" | 114.2 | 0.927 | 10740 | 49.2 | 143.1 |

76*38*2.6 мм | 3" | 90 | 0.929 | 3420 | 63.5 | 112.3 |