Cone Classifier

UralActiv Ltd. company offers to manufacture classifier from thermoplastic materials. The main polymers used for manufacturing are polypropylene and polyethylene. These materials have a great advantage compared to steel construction: high resistance to abrasion and to corrosion cracking. This ensures durability of equipment.

Classifier is a device for the separation of basic material into two or more classes according to the рarticle’s size without the use of screening surface. This separation process is based on differences in rate of the hindered falling of heavy and small particles in the medium at rest or in the moving medium. The pulp in the classifier is divided into two or more products (fractions) of different size.

Classifier is a device for the separation of basic material into two or more classes according to the рarticle’s size without the use of screening surface. This separation process is based on differences in rate of the hindered falling of heavy and small particles in the medium at rest or in the moving medium. The pulp in the classifier is divided into two or more products (fractions) of different size.

AREAS OF APPLICATION FOR CLASSIFIER

- Non-ferrous metal companies and ironworks;

- building industry;

- as dewaterer at concentrating mills.

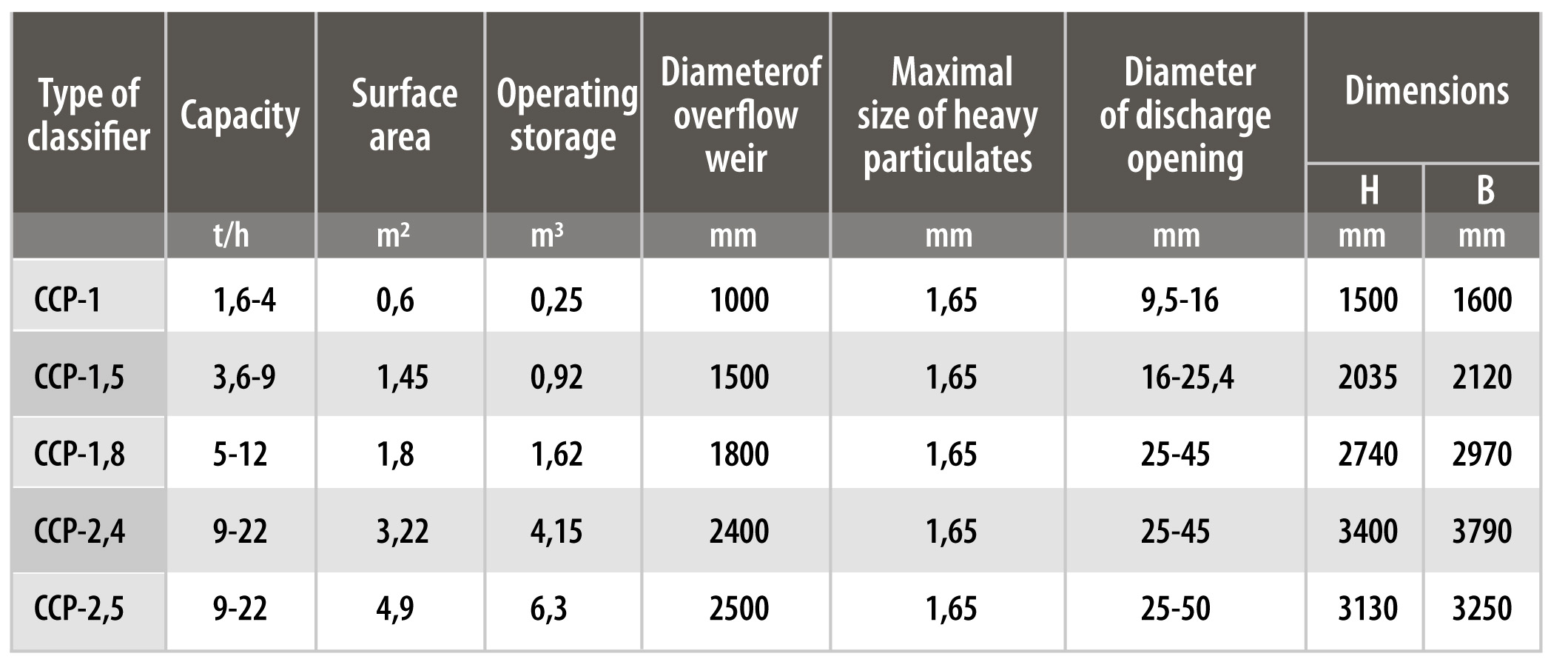

TECHNICAL CHARACTERISTICS

OPERATING PRINCIPLE

Cone classifiers realize a principle of classification in horizontal flow. The feed pulp flows through the pipe into the center of cone where the heavy particles are fractioned. Small fraction is removed by the upflow, runs over the upper cone generatrix into the circular groove, and gets through the drain pan into the branch. Heavy fraction settles and accumulates at the bottom of cone housing. Heavy particles sink on the bottom and are removed through the discharge opening.